|

Outdoor load disconnectors, produced in

accordance with the Driescher company´s documentation,

used for several years on high-voltage long-distance lines,

have proven their high reliability and safety of operation.

Load disconnectors are intended particularly for terminal

branchings in radial arrangement.

Load disconnectors satisfy standards IEC 129, IEC 694

and IEC 420. Using insulators satisfy the third grade

of contmination area according.

Simple load disconnectors of a sturdy structure proved

themselves in an excellent way under very different climatic

conditions.

The foundation welded frame is made of open steel profiles

which guarantee perfect surface protection from corrosion

caused by heat zinc coating that can be controlled on

all places. The shafts of the load disconnectors mounted

in bronze bearings as well as all other steel components

are protected by heat zinc coating, too.

Switching takes place in a tightly closed extinguishing

chamber, filled either with Shell Diala D transformer

oil or biologically degradable Shell FLUID 4600 transformer

oil.

With regard to this fact, Fla type load disconnectors

meet the extreme environmental requirements.

The biological degradation ability of the Shell FLUID

4600 oil was tested and is guaranted by the Deutsche Shell

AG company. Measurements were carried out in accordance

with the international methodics CEC-L-33-A.93.

All current conduction components are made of silver plated

electrolytical copper and constitute a loopless current

conduction path.

The cross-section of the conductors on the current conduction

path is sufficiently dimensioned. Appropriate contact

pressures of the stainless steel springs ensure optimum

prerequisites for faultless switching even after several

years of the load disconnector operation under extreme

operating conditions as well as under load.

The load disconnectors are delivered with such made of

a cyclo-aliphatic resin or porcelain bearings.

The load disconnectors can be provided with earthing switches

located on the under side. The use of earthing switches

requires a double or triple drive with a sturdy blocking

mechanism preventing incorrect handling. The number of

pull rods and pendulum bearings is correspondingly increased.

Control of the load disconnectors and earthing switches

is ensured by means of hand, possibly motor outdoor drives.

The load disconnectors can be provided with encased auxiliary

switches (IP 44 protection) installed directly on the

frame of the device ensuring thus reliable switching-on

and switching-off signalling.

The values of the short-circuit resistance are kept so

as to ensure an adequately large reserve. These values

apply both for the disconnectors and built-in earthing

switches.

The construction of the load disconnectors and the quality

of the materials being used ensure low cost operating

conditions and maintenance.

Under normal operating conditions it is not necessary

for the load disconnectors to undergo a preventive maintenance

during the period of ten years and extinguishing chambers

are not necessary to undergo a preventive maintenance

during the period of sixteen years.

Withstand voltages of Fla 15/6400, Fla

15/6410 and Fla 15/6410 SA load disconnectors

| Rated voltage |

kV |

12 |

25 |

38,5 |

| Rated short-time withstand power frequency

voltage/1min. to be applied in both dry wet environmental

conditions |

| against the earth, across the

poles |

kV |

28 |

50 |

80 |

| across the isolating distance

|

kV |

32 |

60 |

90 |

| Rated lightning pulse withstand voltage

|

| against the earth, accross the

poles |

kV |

75 |

125 |

180 |

| across the isolating distance

|

kV |

85 |

145 |

210 |

Function description

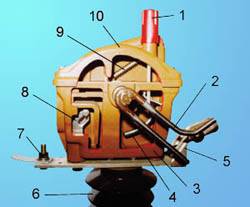

The drawings show the current flow during

switching in switching-on position, intermediate position

and switched-off position of the disconnector.

The contact arm mounted on the pendulum

bearing is provided, on its end, with two rollers (2)

their concave sides being inwards oriented. The extinguishing

chamber (1) is controlled by the stainless-steel forked

contact (3). When controlling the switch, the fork is

positively entrained by the roller both during switching-on

and switching-off. The snap-action mechanism connected

with the said fork acts on the contact system inside the

chamber and closes or opens immediately the contacts of

the extinguishing chamber independently on the speed of

the hand control.

Parallel connection of the switching chambers to the main

circuit.

Sectional view of the extinguishing

chamber

|

|

1. Closure of the filling opening with the gauge

and the air release valve

2. Control lever (made of stainless steel)

3. Bottom part of the extinguishing chamber (sectional

view)

4. Contact rod

5. Main contact

6. Supporting insulator

7. Connecting clamp with a screw

8. Auxiliary contact

9. Snap-action mechanism

10. Upper part of the extinguishing chamber (sectional

view) |

|